Navigation überspringen

- Produkte

- Dienstleistungen

- Anwendungen

- Über uns

- Karriere

- Downloads

Navigation überspringen

- Produkte

- Elektrisches Beheizen

-

Elektrische Heizelemente (MoSi2) bis 1820°C Elementtemperatur

Elektrische Heizelemente (MoSi2) bis 1820°C Elementtemperatur

MolyCom®-Ultra

MolyCom®-Ultra

-

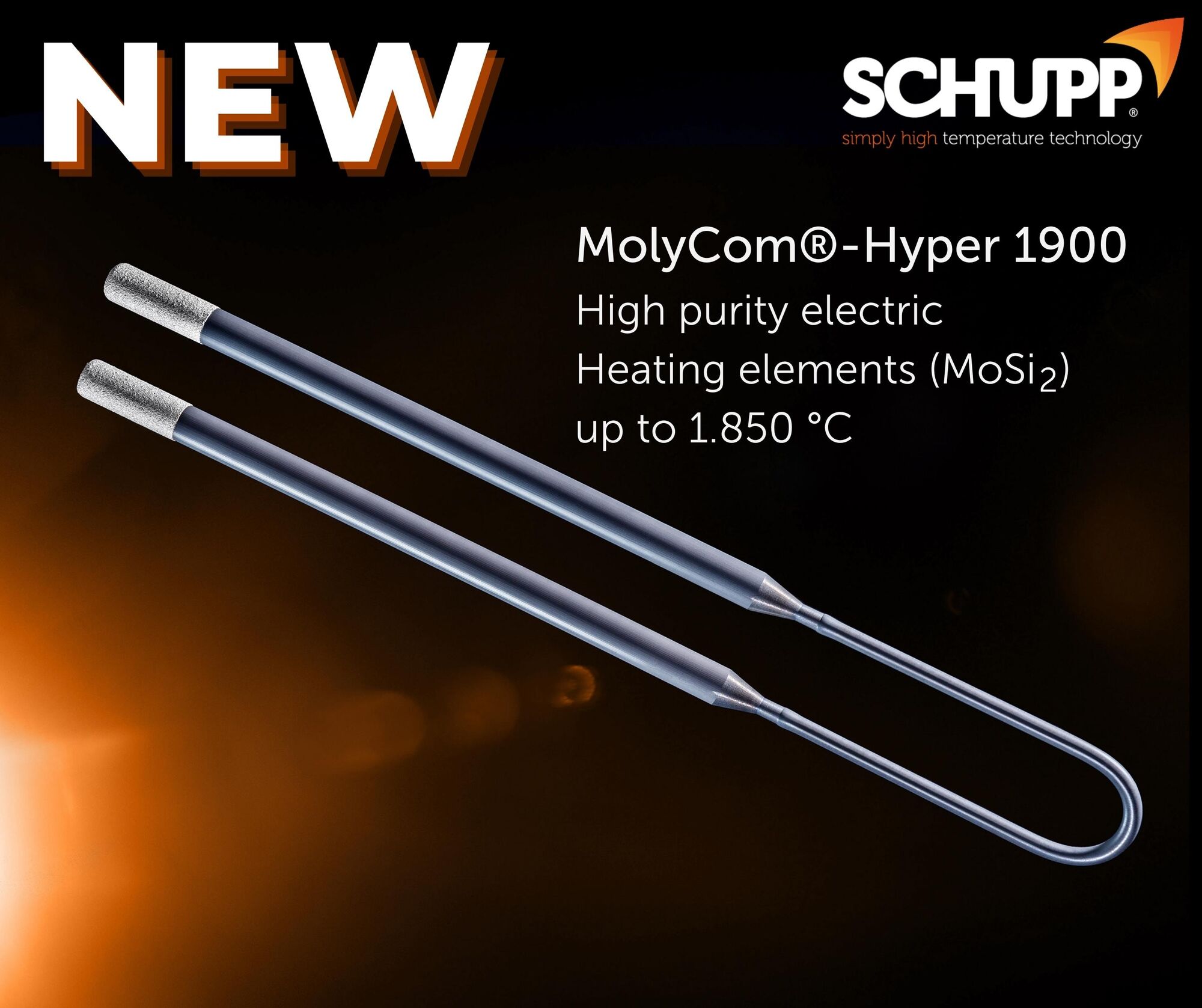

Hochreine elektrische Heizelemente (MoSi2) bis 1850°C Elementtemperatur

Hochreine elektrische Heizelemente (MoSi2) bis 1850°C Elementtemperatur

MolyCom®-Hyper

MolyCom®-Hyper

-

Elektrische Heizsysteme (MoSi2 + PCW) bis 1550°C Anwendungstemperatur

Elektrische Heizsysteme (MoSi2 + PCW) bis 1550°C Anwendungstemperatur

MolyTec

MolyTec

-

Zubehör für den Anschluss elektrischer Heizelemente (MoSi2)

Zubehör für den Anschluss elektrischer Heizelemente (MoSi2)

MolyCom® Zubehör

MolyCom® Zubehör

-

- Thermisches Isolieren

- Brennprozesskontrolle

- Keramisches Kleben

- Brennhilfsmittel

- Elektrisches Beheizen

- Dienstleistungen

- Anwendungen

- Über uns

- Karriere

- Downloads

Temperatur-Finder

Unsere Produkte, Komponenten & Systeme

Unser Newsletter

Melden Sie sich für unseren Newsletter an und verpassen Sie keine Neuigkeiten rund um unsere Produkte und Unternehmen.